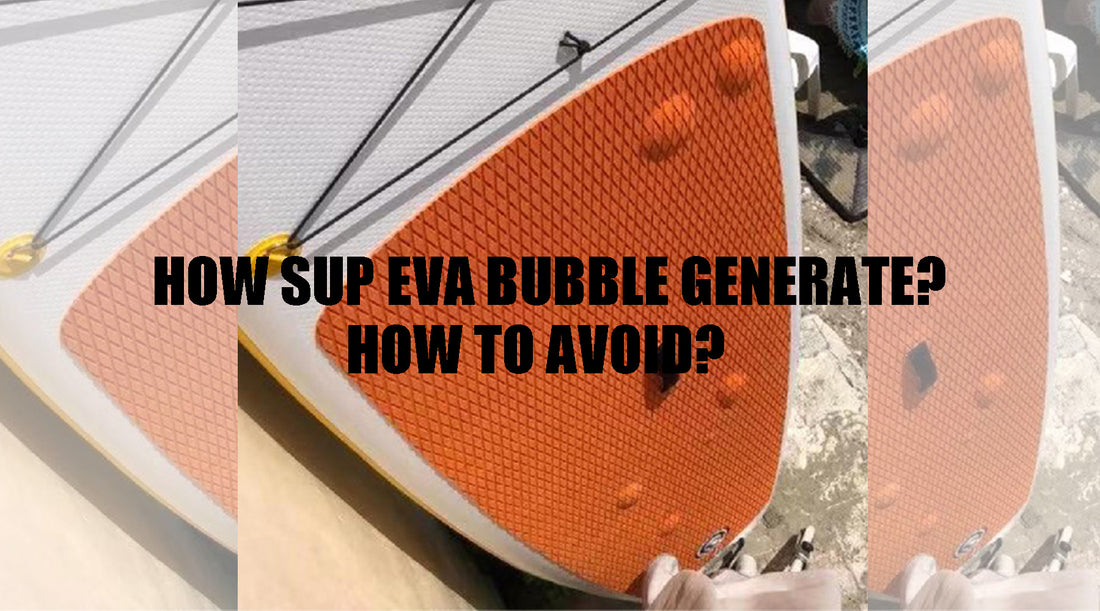

How EVA deck pad bubble generate?

First, let us see from production view,:

Workers adhesive EVA on SUP board body need below step:

-1. brush glue on EVA and board body;

-2. Prick with awl on the backside of EVA; Why don't prick before glued? because glue will clogged the pinhole. Why need prick? Because this process decide EVA deck pad whether have bubble in future, the denser, the better.

-3. Finally roll it with a press machine; Make sure no air inside and glue solid.

But during actual production, workers are paid piece rate, therefore some EVA prick many pinhole, some EVA prick less, these pinhole works when gas generate internal by glue when SUP board experienced sun exposure, these holes will help exhaust air inside.

So pinholes much, bubble none;

pinholes less, bubble chance higher;

As factory we find this problem too, so we thought two methods:

-1. Arrange a quality inspector specialized supervised prick pinholes process, make sure pinholes enough;

-2. Create a prick machine to do this process; Now no this type machine sold on market, only we try to make one in future. If we success made, I will update on this artical.

Thx for your time.

Alan